- Mon to Sat 9:00am to 6:00pm

- +91 9560-9978-48

- anil@crimsonoilfieldservices.com

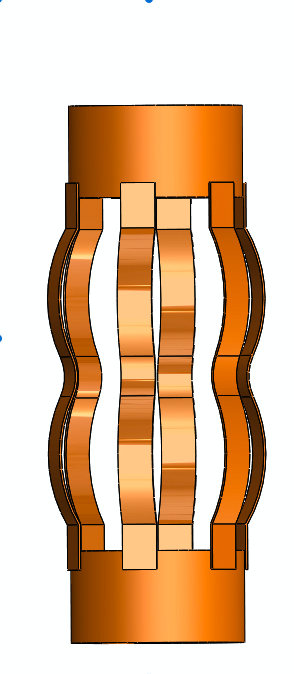

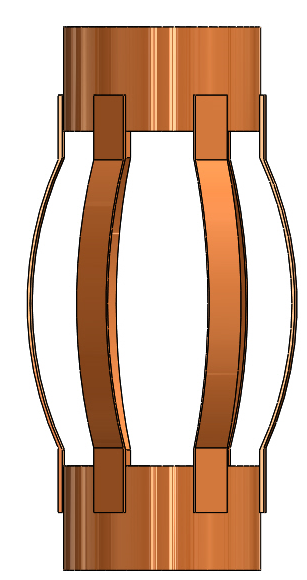

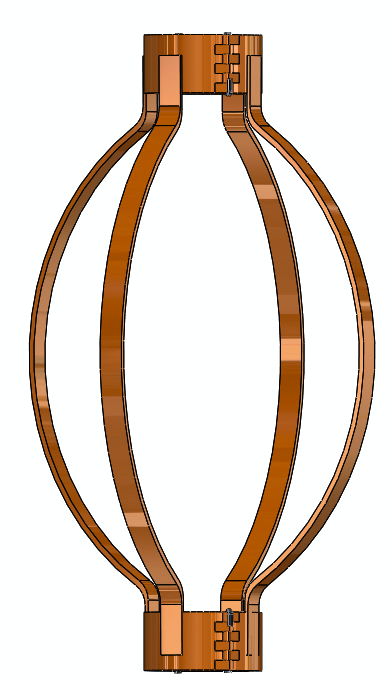

Hinged Non Welded Bow Spring Centralizer

COS’s Hinged Non Welded Bow Spring Centralizers are designed for High Restoring Force and Low Starting & Running Force for centralizing the casing pipe in Vertical, Horizontal and Deviated well.

Premium quality Bows are made of special Double Rolled Alloy Steel and hot formed in totally controlled

Heat Treatment Plant to achieve the uniform hardness all over and good spring action. End Collars are designed with self-locking action, which are easy to assemble, time saver and having strong grip. The five standard sizes Bows can configure to any hole dia. These Bows with extended profile prevent them from hitting against casing collars. These Centralizers undergo a special Iron Phosphate coating process to prevent from Rust and then coated with special Polyester Powder.

These can be shipped in half assembled condition for economical in shipping and storage costs. These are available in 2 7/8" to 30 " sizes. Any special sizes or combination can be made available on request.

Features :

- API certified – engineered and tested to exceed API 10 D

- Low insertion & running forces

- High restoring forces

- Suitable for passing through wellbore / cased hole restrictions

- High quality spring steel grade

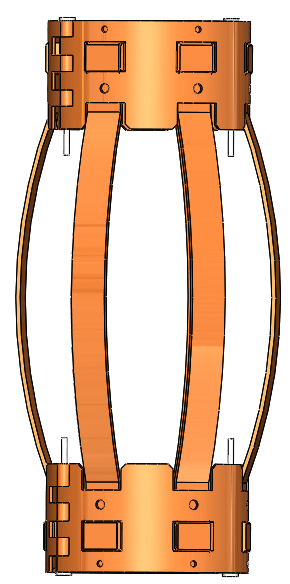

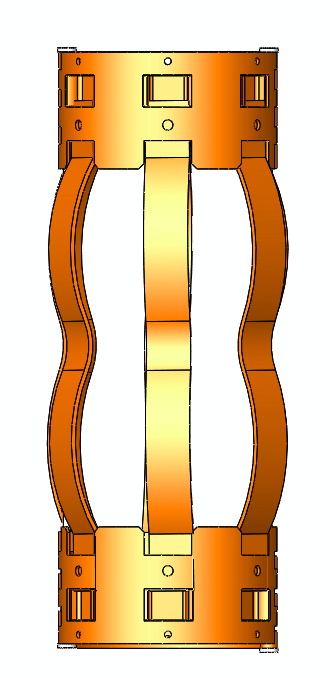

Hinged Welded Bow Spring Centralizer

COS's Welded Hinged Spring Bow Centralizers are high quality welded products, which meet or exceed API 10D specification. Welded Centralizer has more Restoring Force as compare to Non Welded Centralizer.

The Centralizers have Bow Spring strongly welded to the End Collar under required temperature and condition with extra low Hydrogen coated Electrodes. Integral hinge folded on the inside stay intact even under extreme stress. The End Collars are designed with a Reinforcing Rib stamped into the End Collar to give maximum structural toughness. These are available in 2 7/8" to 30 " sizes. Any special sizes or combination can be made available on request.

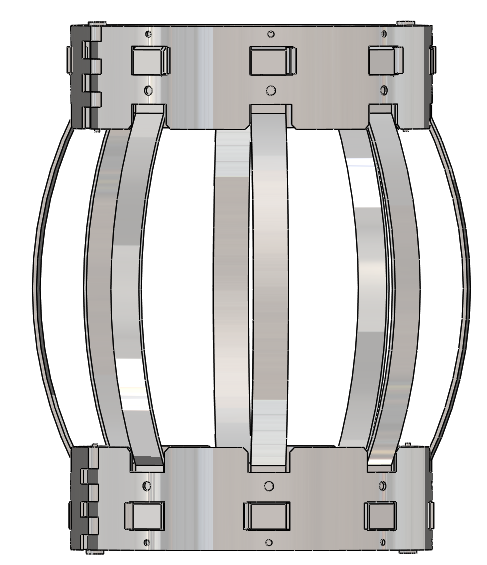

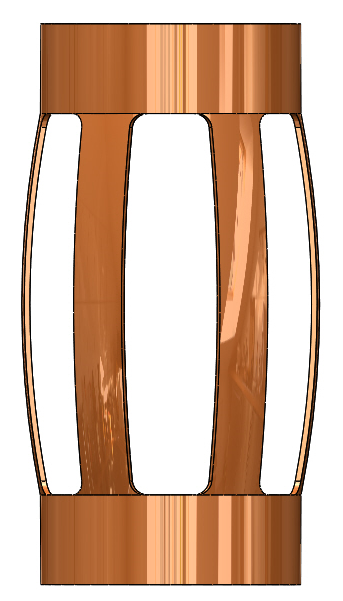

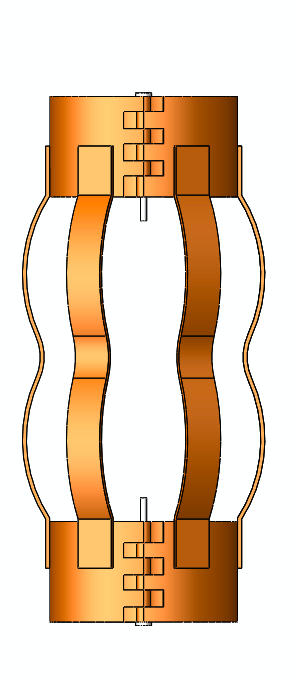

Slip On Welded Bow Spring Single Piece Centralizer

COS's Slip on Welded Bow Spring Single Piece Centralizer is made with one piece welded at one side. Premium quality Bows have high restoring force uniform hardness all over. Slip on centralizers are provided for direct installation pipe by slipping on. It has High tensile strength, high shock absorption value and impact value. In welded centralizers, welding can never be as smooth as the single piece centralizer.

Welding always be little overlapped or little exposed which cause friction to fluid while running in the hole but single piece centralizer have smooth corner radius which allow better fluid by pass and have low friction. This centralizer undergoes a special Iron Phosphate coating process to prevent it from rust and coated with special Polyester Powder. It is shipped in assembled condition only.

These are available in all sizes ranging from 2 7/8" to 30". Any special sizes or combination can available on request.

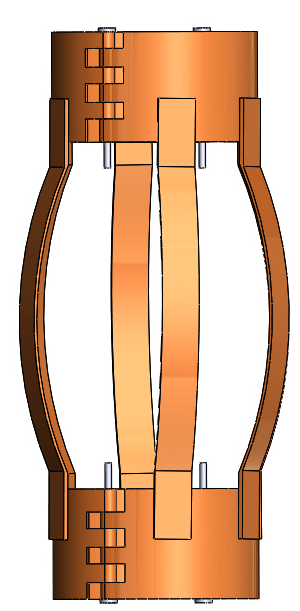

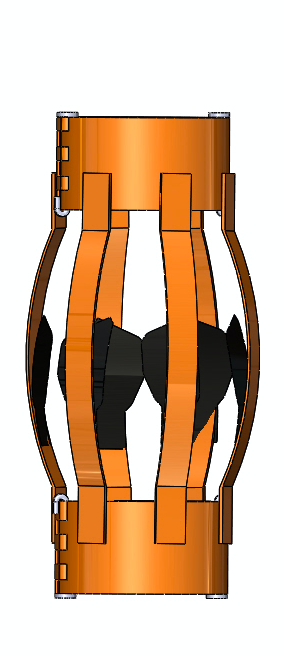

Hinged Non Welded Positive Rigid Bow Spring Centralizer

COS’s Non welded positive Centralizers are uniquely designed with flat bottom U profile of different depths. The Centralizers significantly reduce frictional drag while being used in deviated holes. They provide almost 100% Stand Off when run inside a cased hole. They are supplied 1/4" or 6 mm less than the inside diameter of the hole size in which Centralizer is to be run. This design eliminates weak (brittle) spots passage. U profile bow design permits maximum fluid passage.

End Collars are designed with self-locking action, which are easy to assemble, time saver and have strong grip. The Ten special U sizes Bows can be configured to any hole dia. These Bows with extended profile prevent them from hitting against casing collars. Bows are of high quality steel for consistent characteristics.

These centralizers undergo a special Iron Phosphate coating process to prevent from Rust then coated with special Polyester Powder. These can be shipped in half assembled condition for economy in shipping and storage costs.

These are available in all sizes ranging from 2 7/8" to 30". Any special sizes or combination can available on request.

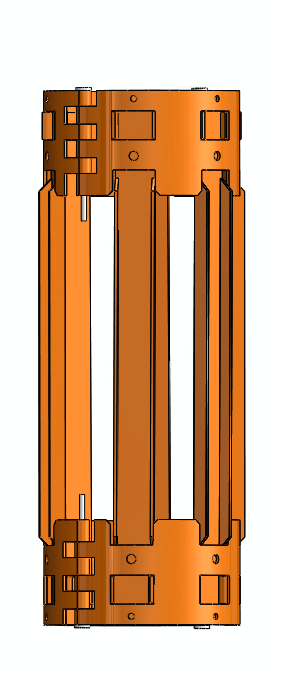

Hinged Welded Drill Pipe Centralizer

COS's Drill Pipe Centralizer Runs freely into difficult well-bores while providing excellent standoff. The Bows of these Centralizers are heat treated in special furnace which gives it a peculiar ‘bow spring’ action. The Heat Treated bows enable these centralizer to provide best centralization as well as help in faster running of casing.

In this type of Centralizers the End Collars have hinges which makes it in two halves. The longer bow profile allows centralizers to be pulled into restrictions and into larger under reamed open hole.

Slip On Welded Bow Spring Turbolizer

COS’s Slip On Welded Bow Spring Turbolizer’s Operational, General design, Features and Characteristics are the same as Hinged Welded Turbolizer. Collars are specially designed with roll formed peripheral ridges which provide extra rigidity. Slips On Turbolizers are provided for direct installation on pipe by slipping on and can be provided with Setscrew for elimination of Stop collar. They are shipped in assembled condition only. These Centralizers undergo a special Iron Phosphate coating process to prevent from Rust then coated with special Polyester Powder.

These are available in all sizes ranging from 2 7/8" to 30". Any special sizes or combination can available on request.

Slip On Welded Semi Rigid Bow Spring Centralizer

COS’s Slip On Welded Semi-Rigid Centralizers share many of the same design and operational features as Hinged Welded Centralizers. They can be directly installed onto pipe and are provided with set screw style Stop Collars to increase the holding force. The Collars are innovatively designed with roll formed peripheral ridges that provide extra rigidity. The Centralizers are available in a variety of Bows configured from a choice of four standard Bow heights..

These are available in all sizes ranging from 2 7/8" to 30". Any special sizes or combination can available on request.