- Mon to Sat 9:00am to 6:00pm

- +91 9560-9978-48

- anil@crimsonoilfieldservices.com

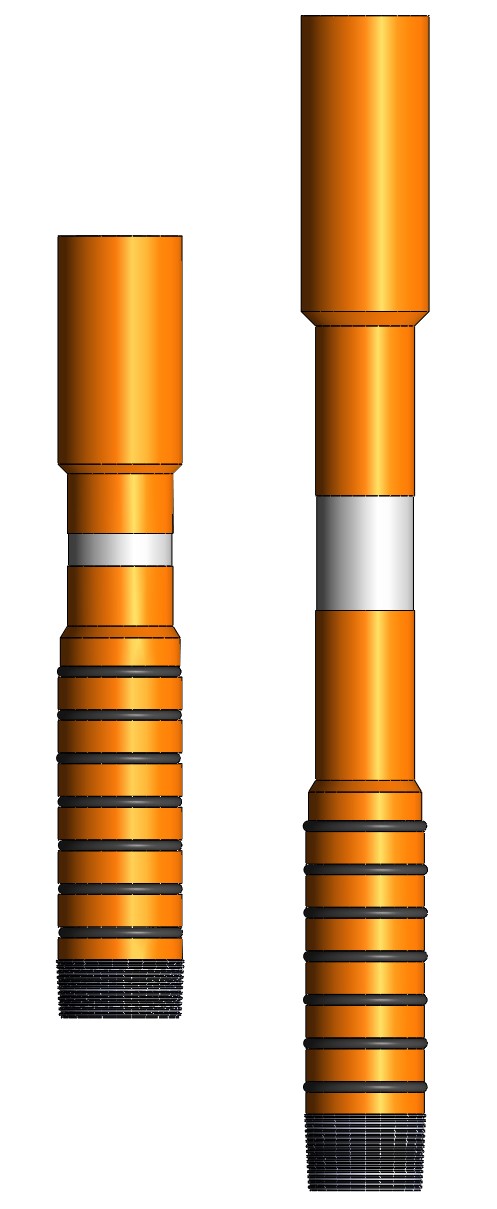

COS One Trip Hydroset

The COS One Trip Hydroset Packer is a Hydraulic Set, Dual Bore Packer for placing short or long tailpipe liners in Horizontal or Extended Well Bores. This Permanent Packer has high tension load capability to make it a perfect choice when liner systems need to be anchored in place. As a double grip packer, the Dual Bore Permanent Packer Prevents both upward and downward movement once the tool is set in place. Being a completely hydraulic set packer, the Dual Bore Permanent Packer does not require any setting string manipulation to set the packer.

Use of a Dual Bore PBR Allows for the maximum ID thru the Tool and any Seal Assemblies to allow for the tool to be on size with the liner.

Features :

- Vertical and Horizontal Well Bore Applications

- Double Grip to prevent liner movement after set

- Completely Hydraulically Set, No Setting String movement required

- Internal Locking, no force required to be left on the tool

- Shear Pins allow for adjustments of setting pressure

Different elastomers and materials available for hostile environments

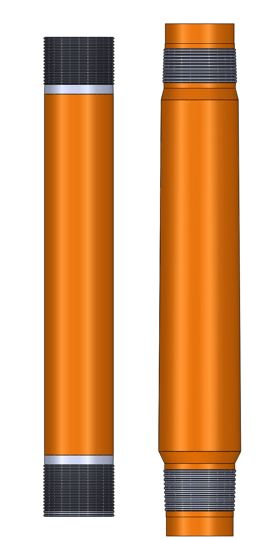

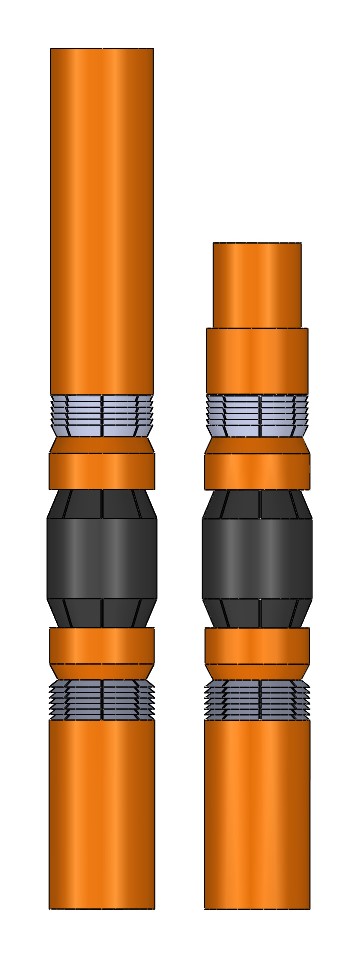

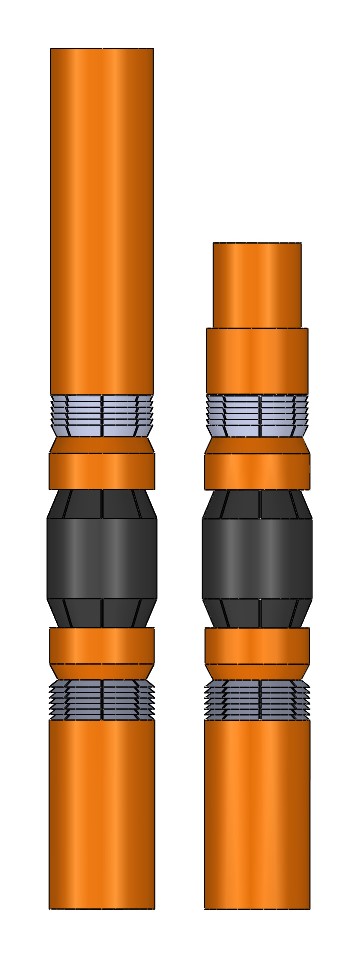

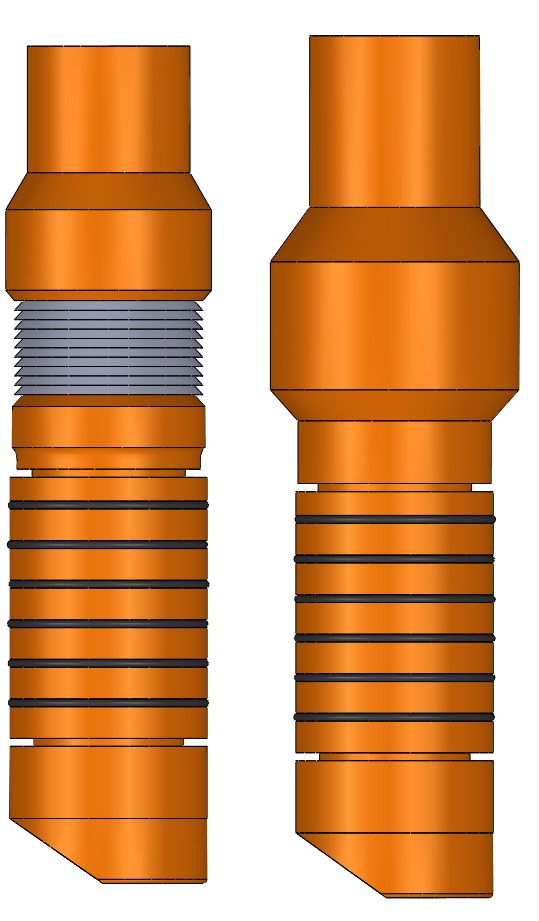

Model “J” & “L” Permanent Production Packers

The COS Model “J” & “L” Production Packers are available to fit your needs and provide the versatility of our excellent pack-off system for a positive secure set in the well bore.

These packers assist in the economical operation of a variety of completion and production jobs. They are designed to accommodate seal bore extensions used in deep wells requiring a longer seal bore interval. Seal Nipples are available with either automatic square-thread latch or locating shoulder. These packers can be used as test tools. Full opening bores allow the passage of perforating guns used to perforate a zone below for testing. If the zone proves to be non-productive, the packer can be used as a squeeze tool.

The packers are designed to provide high-impact resistance and a dependable seal. The high quality packing system will conform to the casing and close off any extrusion of rubber, as the packer is set, even at high temperatures and pressures.

COS’s Model J Production Packers provide excellent clearance for run-in while the COS Model “L” Production Packers offer a larger seal bore. The two models carry different pressure ratings noted later in this document.

R22 is the designation for standard service that COS puts on the equipment listed below. Equipment for service other than standard can be specified upon request from the customer.

For additional information, please contact COS or an authorized representative.

Features :

- E.C.N.E.R. Array packing element system

- One piece slips hardened to depth of wicker only

- Sets in any grade casing including P-110

- Choice of bottom to fit your application – specified when ordering

- Ratcheting lock ring holds setting force

Availability :

- Model J’s – 4 1/2 thru 9 5/8 Casing

- Model L’s – 5 1/2 thru 7 5/8 Casing

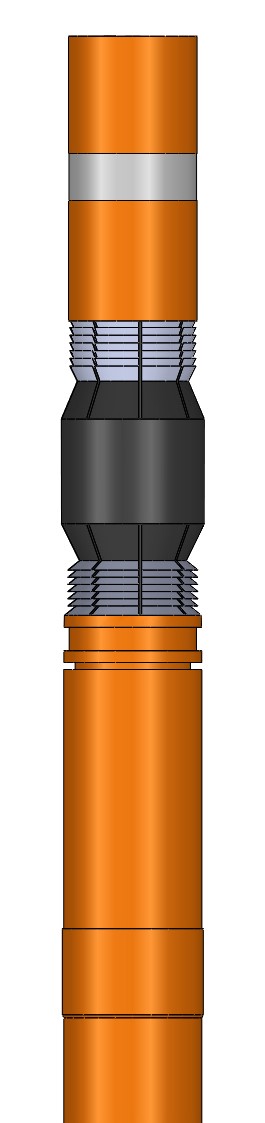

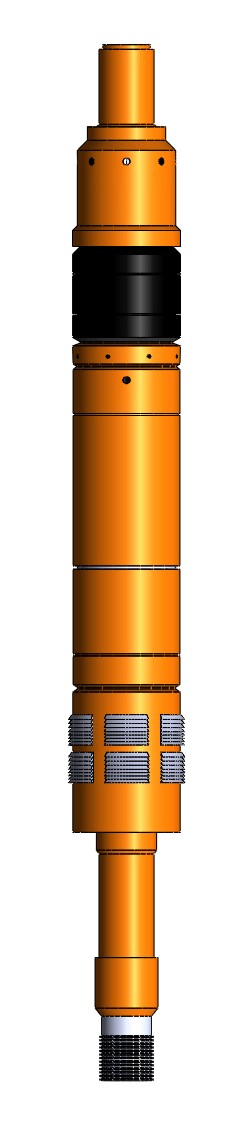

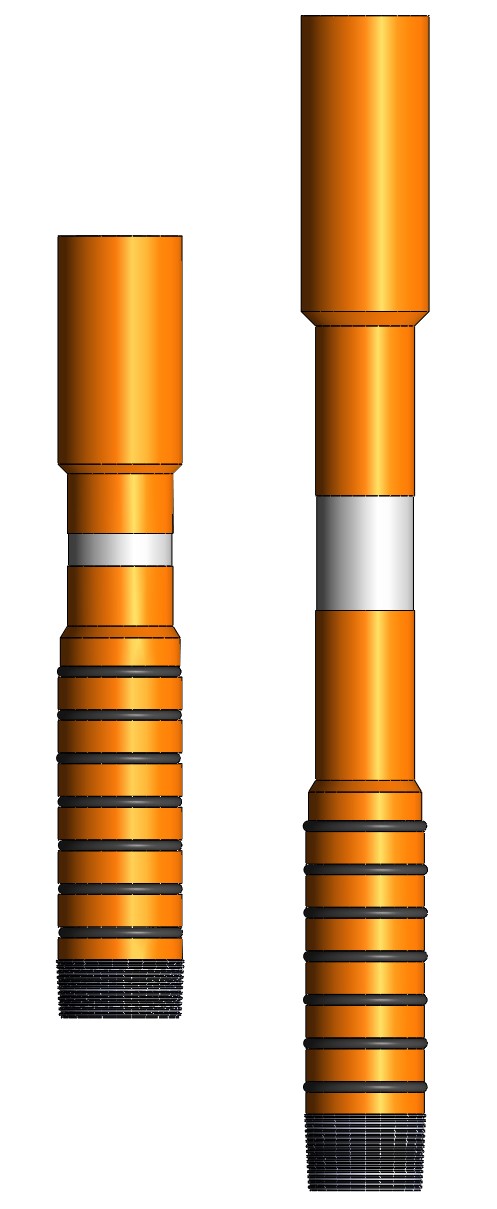

Model “SRHP” Single String Retrievable Hydraulic Packer

The COS “SRHP” is a pure hydraulic set packer that can be run in single or multiple zone installations. It is highly recommended for deviated wells where conditions are not suitable for mechanical or wireline set packers.

No tubing movement is required or generated in order to set the packer. This allows the well to be kept positively controlled at all times because the tubing is landed and the wellhead installed before circulating or displacing well fluids prior to setting the packer. Two or more packers can be set either at once or in any desired sequence.

The SRHP packer design features bi-directional, one piece slips located below a three element packing system consisting of dual durometer rubber elements. The slips are fully enclosed in a shear pinned slip housing which in turn is protected by a full diameter guide located below the slip housing.

The SRHP packer requires a means of establishing a maximum of 3,500 psi pressure inside the tubing at the packer (for 7″ and smaller). The hydraulic setting chamber is adjustable between 900 to 2,500 PSI which allows the tubing to be pressure tested before the packer begins to stroke and set. Two balanced pistons are utilized during the setting process. The lower piston moves down to set and anchor the slips before the upper piston moves upward to compress the packing. This action imparts the total setting force to both slips and packing thus assuring a positive anchor and pack-off. The pack-off is retained by a one-piece ratchet ring that locks in and stores the setting force applied to both the slips and packing elements.

The SRHP packer incorporates two methods of release, straight pull or rotation. Both methods are contained in the same releasing nut which is located at the upper end of the packer. Straight pull release is accomplished by shearing a predetermined quantity of brass retaining screws which frees the tubing.

Rotation release is accomplished by approximately eight right hand turns of the tubing which also frees the packer. Straight pull then is applied to completely relax the packer for retrieval. The SRHP packer can be ordered with only one method of release if desired. A positive acting equalizing valve is also located in the releasing section which automatically opens during the releasing procedure to equalize pressures and allow circulation between the annulus and tubing. In addition, a large diameter fluid by-pass is located inside the packing mandrel which allows fluid passage for rapid retrieving while reducing element swabbing

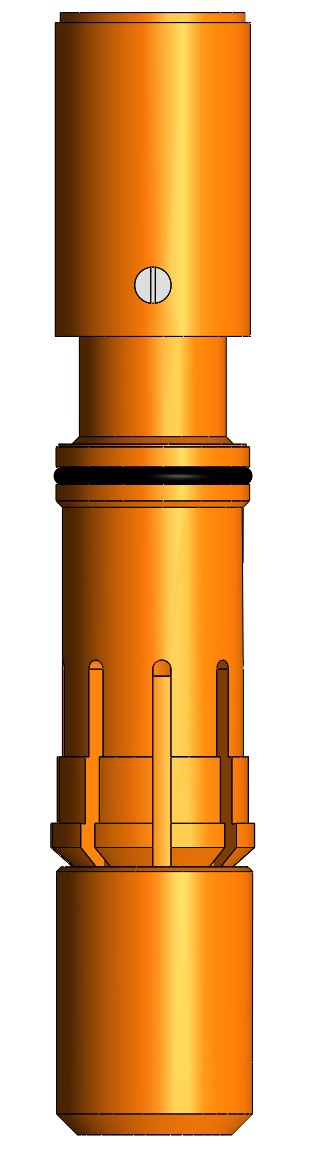

Seal Nipples Production Packers

COS Model 8 Anchor Latch Type Tubing Seal Unit–

Designed for latching the tubing string to the packer. Used where well conditions require the tubing to be landed in tension or where insufficient tubing weight is available to prevent seal movement. Production tubes, tailpipe and other accessories can be added below.

COS Model C Locator Type Tubing Seal Unit–

Designed for limiting downward movement of the seals in the packer bore. Normally landed with the tubing in compression sufficient to prevent seal movement upward. Any number of seal units can be added for increased length. Production tubes, tailpipe and other accessories can he added below.

Seal Spacers(Packer Accessories)

Model B Non Locating Tubing Seal Unit

Intended for use as the lower seal assembly in multiple packer installations. With sufficient seal units mis-measurement or tubing movement can be accommodated. Production tubes, tailpipe and other accessories can be added below.

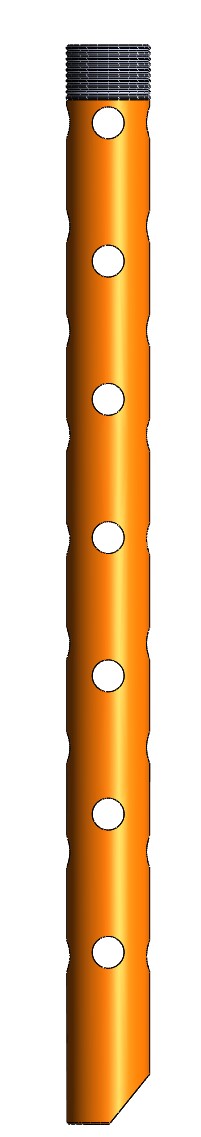

Spacer Sub Seal Units

Are used to add length and additional seal stacks to Model “C” Locator Tubing Seal Units or Model “B” Tubing Seal Units. These units allow for assembly of long seal lengths without building up excessive seal friction. With these, one set of seals will always be in the packer seal bore.

Spacer Tubes

Are used for spacing out seal units when seal bore extensions are in use. Available in lengths of two, four, six, eight and ten feet. Other lengths made upon request.

Add-on Seal Units

Are used to add additional seal stacks to Model “C” Locator Tubing Seal units and Model “B” Tubing Seal Units. Any number may be used to accommodate expected tubing movement. With these, two sets of seals will always be in the packer seal bore